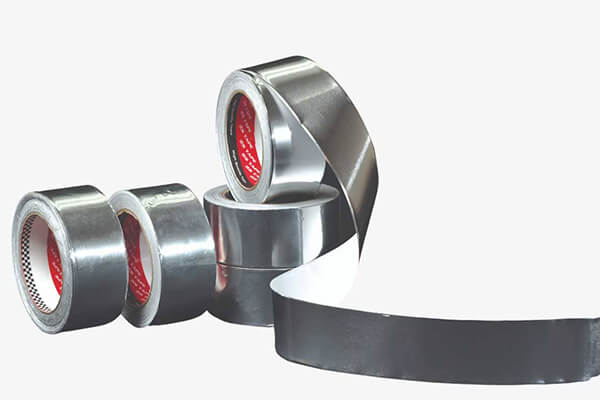

شريط رقائق الألومنيوم

| درجة السبائك | 1100,1235,3003,8011 |

| سماكة | 0.05-3مم |

| عرض | 80-2800مم |

| طول | التخصيص |

| سمات | العزل, waterproofing, heat preservation |

| طلب | التغليف, خطوط الأنابيب, الإلكترونيات, بناء, العزل |

Introduction to Aluminum Foil Tape

Aluminum foil tape is a multifunctional adhesive material and a composite film used for packaging, printing, electronic appliances, food and beverages and other products. Aluminum foil tape is a tape material composed of aluminum foil and adhesive. رقائق الألومنيوم, as the main material, has the characteristics of light weight, مقاومة التآكل, and good thermal conductivity, while the adhesive can make the aluminum foil firmly bonded with other materials. The unique structure and material of aluminum foil tape make it widely used in various industries.

Material of Tape Aluminum Foil

The material of Aluminum tape foil usually involves the following key aspects: aluminum foil substrate–لاصق–backing material–surface treatment.Most of the tapes used in daily life are plastic and cloth materials, and aluminum foil tape is a kind of tape used in special fields.

So what is the material of aluminum foil tape?

The base material of aluminum foil tape is aluminum foil, and the adhesive layer is coated with acrylic or rubber pressure-sensitive adhesive. Some aluminum foil tapes are also compounded with a layer of plastic to improve the tensile strength of aluminum foil, which has good high temperature resistance, heat preservation, and electromagnetic shielding functions. Because the material of aluminum foil tape is polyester fiber, it is not easy to crack or damage after repeated use or multiple bending, and can be easily wrapped and attached to the wire, so it is used in many fields.

Aluminum foil tape base material

The base material of tape foil is generally aluminum foil. In the 1000-8000 مسلسل, there are several alloy grades in the 1xxx, 3xxx, and 8xxx series that are very suitable for the production of tape foil.

Aluminum foil tape alloy type

1100 aluminum foil tape

1100: Widely used due to its high aluminum content and excellent thermal conductivity.

1100 tape aluminum foil refers to a tape-shaped aluminum foil material made of 1100 سبيكة الألومنيوم. It has unique properties and a wide range of applications and is very popular in the fields of industry, الإلكترونيات, food packaging, إلخ.

الألومنيوم 1100 foil tape alloy composition

1100 aluminum foil is mainly composed of the following components:

| الألومنيوم (آل) | السيليكون + حديد (و + الحديد) | نحاس (النحاس) | المنغنيز (من) | الزنك (الزنك) | عناصر أخرى | المجموع |

| 99.00% دقيقة | ≤ 0.95% | 0.05 – 0.20% | ≤ 0.05% | ≤ 0.10% | ≤ 0.05% each | ≤ 0.15% |

The high aluminum content of 1100 aluminum foil ensures its excellent thermal conductivity and reflectivity. The thickness is usually between 0.006mm and 0.025mm, depending on the application requirements. It can be heat-sealed with plastic film or other materials to form a sealed package. It has excellent gas, water vapor and light barrier properties, which helps to extend the shelf life of the product.

1235 aluminum foil tape

1235: With high purity (99.35% – 99.70% الألومنيوم), it is suitable for applications requiring high reflectivity and high thermal conductivity.

1235 tape aluminum foil is a high-performance aluminum foil material with an aluminum content of more than 99.35%. The content of impurity elements such as Si, الحديد, النحاس, من, ملغ, كر, Ni, الزنك, V, ل, Zr, إلخ. is strictly controlled. As the base material of the tape, 1235 aluminum foil can provide excellent adhesion and protection performance. سمك 1235 tape aluminum foil is usually between 0.007-0.2mm, and the width range is 100-1700mm.

3003 aluminum foil tape

3003: With high strength and good workability, it is used in applications requiring a certain strength.3003 tape aluminum foil is a 3003 aluminum foil tape. 3003 aluminum foil tape is an aluminum foil product made of 3 series aluminum foil raw materials (belonging to the AL-Mn series alloy) through cold rolling or hot rolling. It has the characteristics of uniform thickness, smooth surface, لا توجد ثقوب, no dust particles, and no odor.

The strength is higher than that of 1 series aluminum foil, and is about 10% higher than that of 1100 رقائق الألومنيوم و 1060 رقائق الألومنيوم.

The tape foil 3003 aluminum foil has a thinner thickness while maintaining excellent flexibility, which is suitable for laminating complex shapes.

8011 aluminum foil tape

8011: Commonly used in food packaging and industrial purposes, due to its good corrosion resistance and plasticity.

8011 أشرطة رقائق الألومنيوم:8011 aluminum foil tape is a tape made of 8011 سبيكة الألومنيوم as the base material. It has excellent performance and a wide range of applications. 8011 belongs to aluminum-iron-silicon alloy.

The main components include aluminum (آل), حديد (الحديد) وسيليكون (و). The combination of these elements makes tape foil 8011have good strength and corrosion resistance, while maintaining the flexibility of aluminum foil. 8011 foil tape is coated with a high-performance adhesive layer that adheres firmly to a variety of materials, including metal, زجاج, plastic and composite materials.

Aluminum foil tape adhesive types

Acrylic adhesives: Provide good initial adhesion and durability, suitable for a variety of environments.

Rubber-based adhesives: Provide good adhesion and flexibility, suitable for low temperature environments.

Silicone adhesives: Provide extremely high temperature and chemical resistance, suitable for high temperature or special applications.

Adhesive properties:

Temperature resistance: The adhesive should be able to maintain adhesion over a certain temperature range, usually from -40°C to +120°C.

المقاومة الكيميائية: The ability to resist corrosion from chemicals.

UV resistance: For applications exposed to sunlight, the adhesive needs to be UV resistant.

Aluminum foil tape backing materials

Polyethylene (PE) film: Provides mechanical protection and heat sealing properties.

Polypropylene (ص) film: Provides higher temperature resistance and mechanical strength.

Polyester (حيوان أليف) film: Has high strength and heat resistance, suitable for applications requiring high strength and durability.

Tape aluminum foil surface treatment

طلاء: The surface of the aluminum foil may be coated to improve corrosion resistance, adhesion or provide other specific functions.

Anti-corrosion coating: such as epoxy or polyurethane coating, enhances the corrosion resistance of aluminum foil.

Anti-static coating: used for electronic product packaging to prevent static damage.

Moisture-proof coating: used for food packaging to prevent moisture ingress.

Product types of tape aluminum foil

| Aluminum foil tape without backing paper | Aluminum foil tape without backing paper is the commonly used and common aluminum foil tape. Its main material is basically made of pure aluminum. The base material is flat and bright, the texture is relatively soft, and the adhesion is high. It is often used for pipe sealing, stove waterproofing, or pots and pans repair. |

| Aluminum foil tape with backing paper | Aluminum foil tape with backing paper has an extra layer of backing paper in the middle compared to non-backing paper. It is more commonly used in places where electronic products such as mobile phones, computers, and copiers require electromagnetic shielding. |

| Flame retardant aluminum foil tape | Flame retardant aluminum foil tape is made of pure aluminum foil as the base material and silicone isolation paper with good performance as the backing paper. It is mainly used to block heat and fire sources. It is suitable for wall and steel structure insulation, as well as automobile and train compartment insulation. |

| Fiberglass cloth aluminum foil tape | Fiberglass cloth aluminum foil tape is made of aluminum foil and fiberglass cloth through adhesive. This makes the fiberglass cloth aluminum foil tape have better tensile strength and is more suitable for wrapping and repairing. |

| Reinforced aluminum foil tape | Reinforced aluminum foil tape is a composite material with glass fiber yarn reinforcement between aluminum foil and kraft paper. Compared with ordinary aluminum foil tape, it is more beautiful and durable, and the price is also low. There are two types: single-sided and double-sided. |

| Black paint aluminum foil tape | The black paint aluminum foil adhesive has a layer of black or matte on the outside. It is not used much in daily life. It is mainly used to wrap ventilation ducts in subway stations, underground shopping malls, إلخ. It has the advantages of light absorption, sound absorption, and beauty. |

| Aluminum foil butyl tape | Aluminum foil butyl tape is a blend of aluminum foil, butyl rubber, polyisobutylene and other main raw materials. It has high and low temperature resistance, wear resistance and waterproof properties. It is used for waterproofing cracks in open-air balconies, الأسطح, زجاج, لون البلاط الصلب, خطوط الأنابيب, إلخ. |

Aluminum foil tape uses

What are the uses of aluminum foil tape? Aluminum foil tape is a multifunctional material. It is widely used in various fields due to its high viscosity, العزل الحراري, مقاومة الرطوبة, مقاومة التآكل, electrical insulation, high temperature resistance and other characteristics. What is aluminum foil tape used for?Aluminum foil alloy tape can play a role in construction, احباط العسل, food packaging, و التعبئة والتغليف الصيدلانية.

Air conditioning pipe wrapping:

Aluminum foil tape is often used for wrapping air conditioning pipes to ensure the insulation and sealing performance of the pipes.

Home appliance repair and protection:

When repairing home appliances, aluminum foil tape can be used to wrap, protect and fix electrical circuits, such as air conditioners, televisions, الثلاجات, إلخ. Its waterproof, insulating and high temperature resistant properties make it an ideal choice for electrical appliance repair.

العزل الحراري:

Aluminum foil tape can be used for seam bonding of thermal insulation materials and repair of damaged parts to enhance thermal insulation and reduce heat loss.

Waterproof and moisture-proof:

In places such as roofs and basements that require waterproofing and moisture-proofing, aluminum foil tape can effectively block moisture penetration and protect buildings from moisture.

Sound insulation:

Aluminum foil tape also has a certain sound insulation effect and can be used to improve the sound insulation performance of buildings.

Automobile manufacturing and maintenance:

During automobile manufacturing and maintenance, aluminum foil tape can be used to protect the car shell and internal parts, enhancing the car’s waterproof, dustproof and corrosion resistance. At the same time, it can also be used for insulation protection and fixation of automobile lines.

Electronic product production and maintenance:

Aluminum foil tape is favored in electronic product production and maintenance due to its electrical insulation and high temperature resistance. It can effectively protect the circuits and components of electronic products from damage.

Electromagnetic shielding:

Aluminum foil tape can be used to shield electromagnetic interference and protect electronic equipment from electromagnetic radiation.

Product packaging:

Aluminum foil tape can be easily adhered to the surface of various materials of goods to form a waterproof and dustproof protective layer, extending the shelf life of the goods and improving the quality.

Gift box lining:

Aluminum foil tape can be used as the lining of gift boxes to enhance the grade and beauty of gifts.

Aluminum foil tape has become an indispensable high-performance material due to its versatility and wide range of applications, and plays an important role in various fields.

Advantages of aluminum foil for tape

Tapes made of aluminum foil show excellent performance and wide application in different fields. Its advantages are mainly reflected in the following aspects:

1. Viscosity and adhesion: Aluminum foil tape uses high-quality pressure-sensitive adhesive, has excellent adhesion and adhesion, and can adhere firmly to various surfaces.

2. Anti-aging: Tape aluminum foil has good anti-aging properties and can maintain stable performance during long-term use.

3. Improved thermal insulation performance: Aluminum foil tape can not only effectively insulate, but also provide sealing at the puncture point of the insulation nail and repair the damaged part. It is widely used in the production of refrigerators, freezers, إلخ.

4. Electromagnetic shielding function: In electronic products, aluminum foil tape plays its electromagnetic shielding function, effectively isolates electromagnetic waves from harming the human body, and prevents the influence of voltage and current on electronic products.

5. Multiple specifications and customized services: Aluminum foil is soft and can be easily processed and compounded. It has various specifications and is suitable for different needs. Huawei Packaging Co., المحدودة. provides customized services of various specifications to meet the personalized needs of customers.